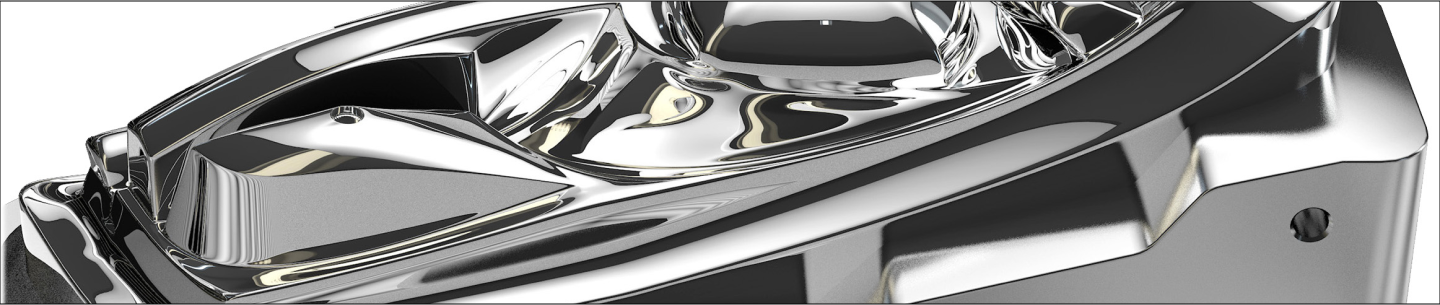

MIRROR POLISHING

Achieving an ultra-smooth and reflective surface, mirror polishing is ideal for parts requiring high aesthetic standards. We use precision tools and high-grade polishing compounds to deliver surfaces with a Ra value as low as 0.02 µm, ensuring smoothness and shine.

TECHNICAL POLISHING

Focused on enhancing the functional properties of moulds, our technical polishing process reduces surface roughness and improves mould release. We combine mechanical and chemical techniques to achieve a consistent finish that enhances durability and performance.

POST-WELD TREATMENT

After welding, surfaces often require refinement. Our post-weld treatment smooths out imperfections and restores the surface integrity of the mould, using advanced abrasive tools and polishing pastes to achieve a uniform finish.

PARTING LINE OPTIMIZATION

Ensuring that parting lines are smooth and precise is critical for mould performance. We meticulously polish these areas to reduce flash and improve the overall quality of the moulded parts, ensuring tight tolerances and accurate dimensions.

EMERGENCY REPAIRS

Accidents happen; when they do, our emergency repair service is ready to respond swiftly. We address surface damage and restore moulds to their optimal condition, minimising downtime and maintaining production quality.

ADDITIONAL SERVICES

Corrosion Repair: We expertly remove corrosion and restore the original surface quality of moulds, using specialised techniques to ensure long-lasting protection.

Form Error Correction: Addressing and correcting any form errors to ensure perfect mould functionality.

Edge Sharpening: Precise sharpening of mould edges to maintain accuracy and improve part quality.

Customer Complaint Resolution: Rapid and effective solutions for any surface-related issues, ensuring complete customer satisfaction.

business inquiry

To get started with your business inquiry, please fill out the form below. This information will help us understand your needs and how we can best support your business.